News

NewsIn the world of manufacturing, precision is paramount. The efficiency and accuracy of machine tools, particularly their spindles, are critical to producing high-quality components. At the heart of these spindles lies a component that often goes unnoticed but is indispensable: the bearing. Bearings play a pivotal role in ensuring the smooth operation, durability, and precision of machine tool spindles, making them a cornerstone of modern manufacturing.

Machine tool spindles are responsible for holding and rotating cutting tools or workpieces with extreme precision. The performance of these spindles directly impacts the quality of the machined parts, the speed of production, and the overall efficiency of the manufacturing process. Bearings, which support the spindle's rotating components, are essential for maintaining the required precision and stability.

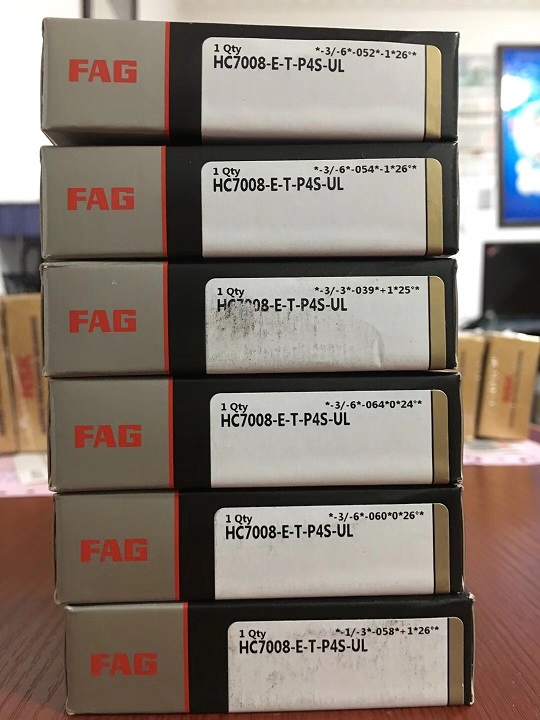

High-speed spindles, in particular, demand FAG bearings that can withstand significant radial and axial loads while operating at elevated speeds. The right bearings reduce friction, minimize heat generation, and ensure consistent performance, even under the most demanding conditions. This is why manufacturers are increasingly turning to advanced bearing technologies to enhance their machine tools.

Recent advancements in FAG bearing technology have revolutionized the capabilities of machine tool spindles. Ceramic bearings, for instance, offer superior performance compared to traditional steel bearings. Made from silicon nitride, ceramic bearings are lighter, harder, and more resistant to wear and corrosion. These properties result in reduced friction, lower heat generation, and extended bearing life, making them ideal for high-speed applications.

Another innovation is the use of FAG hybrid bearings, which combine ceramic balls with steel races. This combination leverages the strengths of both materials, offering improved speed capabilities, reduced vibration, and enhanced rigidity. Hybrid bearings are particularly well-suited for precision machining applications where accuracy and surface finish are critical.

Selecting the appropriate FAG bearings for machine tool spindles is crucial for optimizing performance and achieving the desired outcomes. Factors such as load capacity, speed requirements, operating environment, and precision needs must be carefully considered. Collaborating with a trusted bearing supplier who understands the unique demands of machine tool applications can help manufacturers make informed decisions and unlock the full potential of their equipment.

For more insights on how advanced bearings can transform your manufacturing processes, visit our website and explore our comprehensive range of solutions tailored to meet the demands of modern machine tool spindles. Let us help you achieve the precision and efficiency your operations deserve.