News

NewsAir compressors are the workhorses of countless industries, from manufacturing and construction to healthcare and energy. These machines convert power into pressurized air, which is then used to operate tools, machinery, and systems. At the core of every air compressor lies a component that ensures smooth, efficient, and reliable operation: the bearing. Bearings are essential to the performance and longevity of air compressors, making them a key focus for industries seeking to optimize their operations.

Air compressors operate under demanding conditions, including high speeds, heavy loads, and continuous use. Bearings are responsible for supporting rotating components, such as the compressor shaft, and reducing friction between moving parts. Without high-quality bearings, air compressors would experience increased wear, higher energy consumption, and frequent breakdowns, leading to costly downtime and reduced productivity.

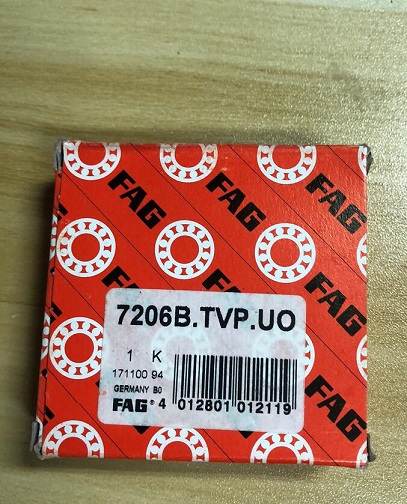

The performance of FAG bearings directly impacts the efficiency, reliability, and lifespan of air compressors. By minimizing friction and maintaining precise alignment, bearings ensure that compressors operate smoothly, even under extreme conditions. This is why selecting the right bearings is critical for industries that rely on air compressors for their daily operations.Need FAG 7206B.TVP.UO,Click here freely.

As air compressor technology evolves, so do the demands placed on bearings. Modern compressors require bearings that can handle higher speeds, heavier loads, and longer operating cycles. To meet these challenges, manufacturers are turning to advanced bearing technologies designed specifically for air compressor applications.

Another breakthrough is the development of FAG high-temperature bearings. Air compressors often generate significant heat during operation, which can degrade traditional bearings. High-temperature bearings are made from specialized materials that can withstand elevated temperatures without losing their performance characteristics. This ensures reliable operation even in the most demanding environments.

Selecting the appropriate bearings for air compressors requires careful consideration of factors such as load capacity, operating speed, temperature range, and environmental conditions. Partnering with a trusted bearing supplier who understands the unique requirements of air compressor applications can help businesses make informed decisions and maximize the performance of their equipment.

FAG Bearings may be small components, but their impact on air compressor performance is enormous. As industries continue to demand greater efficiency, reliability, and durability from their equipment, the role of advanced bearing technologies becomes increasingly important. By investing in high-quality bearings, businesses can ensure their air compressors operate at peak performance, delivering consistent results and driving operational success.

Ready to optimize your air compressors with cutting-edge bearing solutions? Visit our website to explore our range of high-performance bearings designed to meet the demands of modern air compressor applications. Let us help you achieve the efficiency and reliability your business deserves.