News

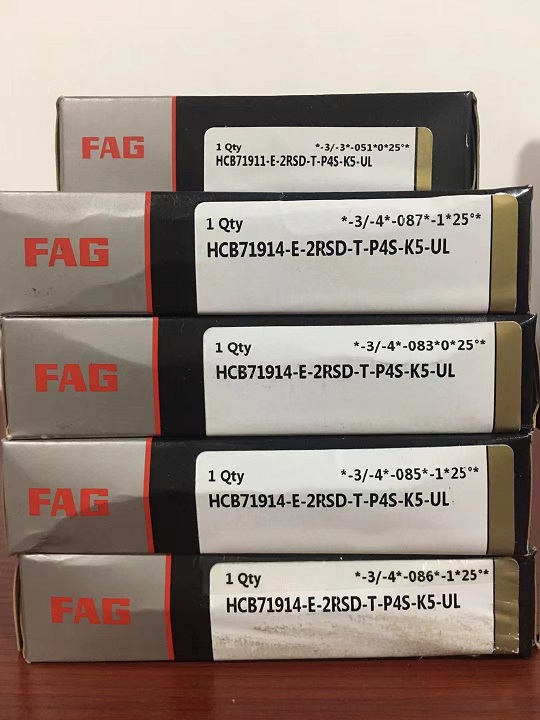

NewsFAG Bearings play a crucial role in agricultural machinery by reducing friction, supporting heavy loads, and ensuring smooth operation under harsh working conditions. Modern farming equipment, such as tractors, combines, and irrigation systems, relies on durable and efficient bearings to maximize productivity and minimize downtime. This article explores the types, functions, and challenges of bearings in agricultural applications.

Load Support

Bearings handle both radial and axial loads in equipment like plows, harvesters, and tillers, ensuring stability during heavy-duty operations.

Reducing Friction & Wear

By minimizing friction between moving parts, bearings enhance efficiency and extend the lifespan of machinery.

Enabling Smooth Rotation

Critical for rotating components in gearboxes, wheels, and PTO (Power Take-Off) shafts.

Withstanding Harsh Environments

Agricultural bearings must resist dust, mud, moisture, and extreme temperatures.

Used in light-to-medium load applications (e.g., electric motors, small gearboxes).

Example: Tractor steering systems.

FAG Roller Bearings (Cylindrical, Tapered, Spherical)

Ideal for heavy loads and shock resistance (e.g., wheel hubs, combine harvesters).

FAG Needle Bearings

Compact design for limited-space applications (e.g., transmission systems).

FAG Plain (Bush) Bearings

Used in low-speed, high-load scenarios (e.g., pivot points in tillage equipment).

FAG Sealed & Lubricated Bearings

Prevent contamination from dirt and water, reducing maintenance needs.

FAG Bearings are vital components in agricultural machinery, ensuring reliable performance in demanding environments. Proper selection—based on load, speed, and environmental conditions—can significantly improve equipment efficiency and reduce maintenance costs. Future advancements in materials and smart bearing technology will further enhance agricultural productivity.